Introduction

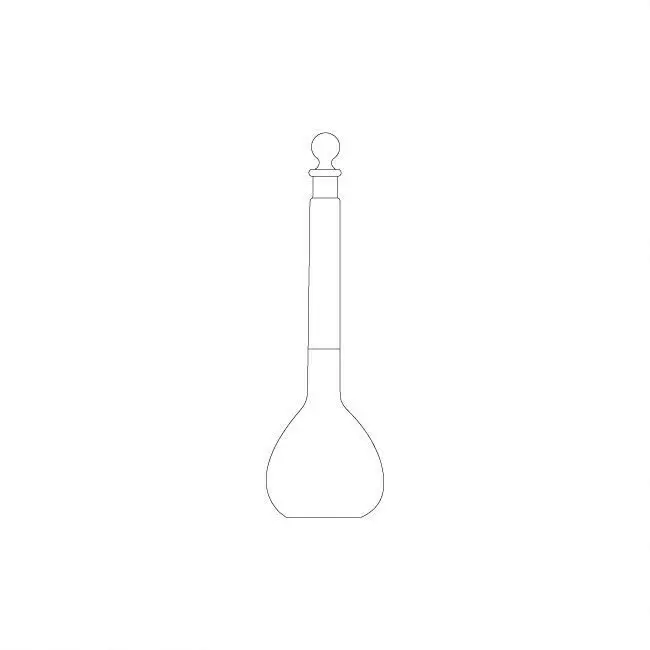

Laboratory equipment manufacturers and educational institutions worldwide rely on precision-crafted glassware for accurate scientific measurements and safe experimental procedures. The Alcohol Lamp Conical Shape,with Ground-in Cap or Plastic Cap represents a fundamental piece of laboratory apparatus that combines traditional design principles with modern manufacturing excellence. This essential heating device serves as a cornerstone for various scientific applications, from basic chemistry demonstrations to advanced research protocols.

Designed with meticulous attention to safety and functionality, this conical alcohol lamp offers researchers and educators a reliable heat source that maintains consistent flame characteristics while ensuring secure fuel containment. The distinctive conical profile not only provides aesthetic appeal but also contributes to improved stability and heat distribution patterns that are crucial for precise experimental conditions.

Product Overview

The Alcohol Lamp Conical Shape,with Ground-in Cap or Plastic Cap features a thoughtfully engineered design that prioritizes both performance and safety in laboratory environments. Constructed from high-grade borosilicate glass, this heating apparatus demonstrates exceptional thermal resistance and chemical compatibility with standard laboratory alcohols and fuels. The conical geometry provides an optimal balance between fuel capacity and compact footprint, making it suitable for various laboratory setups and workspace configurations.

The lamp's versatile cap system accommodates different user preferences and application requirements. The ground-in glass cap option delivers superior durability and creates an airtight seal that prevents fuel evaporation and contamination. Alternatively, the plastic cap variant offers enhanced safety features with its non-breakable construction while maintaining effective sealing properties. Both cap styles incorporate precision-fitted wicks that ensure consistent flame production and easy maintenance procedures.

Manufacturing standards for this alcohol lamp adhere to international laboratory equipment specifications, ensuring compatibility with existing laboratory protocols and safety guidelines. The transparent glass construction allows for easy fuel level monitoring, while the conical shape contributes to enhanced stability during operation and storage.

Features & Benefits

Advanced Glass Construction Technology

The foundation of this alcohol lamp's superior performance lies in its advanced borosilicate glass composition. This specialized material demonstrates remarkable resistance to thermal shock, allowing the lamp to withstand rapid temperature changes without compromising structural integrity. The low coefficient of thermal expansion ensures dimensional stability across varying operating conditions, while the high silica content provides excellent chemical resistance against alcohols and other laboratory solvents.

The precision molding process creates smooth internal surfaces that facilitate easy cleaning and maintenance procedures. The uniform wall thickness distribution enhances mechanical strength while maintaining optimal light transmission for fuel level observation. These construction characteristics contribute to extended service life and reliable performance in demanding laboratory environments.

Dual Cap System Advantages

The innovative dual cap system sets this Alcohol Lamp Conical Shape,with Ground-in Cap or Plastic Cap apart from conventional laboratory heating devices. The ground-in glass cap option provides a hermetically sealed connection that prevents fuel evaporation and maintains consistent alcohol concentration over extended periods. The precision-ground surfaces create an interference fit that eliminates the need for additional sealing compounds while ensuring easy removal for refueling procedures.

The alternative plastic cap design incorporates advanced polymer materials that resist chemical degradation while offering enhanced impact resistance. This option particularly benefits high-volume laboratory environments where frequent handling and potential drops pose risks to traditional glass components. The plastic cap maintains equivalent sealing performance while providing visual and tactile differentiation for inventory management systems.

Optimized Flame Control Characteristics

The carefully designed wick system delivers consistent flame characteristics that meet precise heating requirements across various applications. The wick diameter and material composition work in conjunction with the conical lamp geometry to produce stable flame heights and uniform heat distribution patterns. This predictable performance enables accurate temperature control for sensitive procedures while minimizing fuel consumption rates.

The flame adjustment mechanism allows operators to fine-tune heat output according to specific experimental protocols. The wide adjustment range accommodates both gentle warming applications and higher-temperature procedures, making this alcohol lamp suitable for diverse laboratory techniques and methodologies.

Applications & Use Cases

Educational institutions worldwide incorporate the Alcohol Lamp Conical Shape,with Ground-in Cap or Plastic Cap into their laboratory curricula for fundamental chemistry and physics demonstrations. The reliable flame characteristics make it ideal for teaching proper laboratory techniques, including glassware sterilization, solution heating, and basic flame tests. The transparent construction allows students to observe fuel levels and flame behavior, enhancing their understanding of combustion principles and laboratory safety protocols.

Research laboratories utilize these alcohol lamps for various analytical procedures that require controlled heating applications. The consistent flame temperature proves valuable for qualitative analysis techniques, sample preparation procedures, and equipment sterilization protocols. The portability and independence from electrical power systems make these lamps particularly useful for field research applications and emergency laboratory procedures.

Quality control laboratories in pharmaceutical and chemical industries rely on alcohol lamps for standardized testing procedures that demand reproducible heating conditions. The predictable flame characteristics ensure consistent results across multiple test runs, while the chemical resistance properties prevent contamination issues that could compromise analytical accuracy. The compact design facilitates integration into existing laboratory workflows without requiring significant infrastructure modifications.

Specialized applications include glassblowing and glass repair workshops, where the clean-burning flame and precise heat control enable intricate fabrication techniques. The alcohol fuel produces minimal soot and chemical residues, making it suitable for applications requiring clean heating environments. The conical design provides excellent stability during extended operation periods common in glass crafting applications.

Quality Control & Compliance

Manufacturing processes for this alcohol lamp incorporate comprehensive quality assurance protocols that ensure consistent performance characteristics and safety compliance. Each unit undergoes rigorous testing procedures that evaluate glass integrity, cap fit tolerances, and flame stability parameters. The quality control system includes visual inspections for surface defects, dimensional verification procedures, and functional testing under simulated operating conditions.

Material certification processes verify that all glass components meet international borosilicate glass standards for thermal and chemical resistance properties. The cap materials undergo compatibility testing with standard laboratory alcohols to ensure long-term durability and safety performance. Traceability systems maintain detailed records of raw material sources and manufacturing parameters for each production batch.

International safety standards compliance ensures that these alcohol lamps meet the requirements of major laboratory certification bodies and educational safety guidelines. The design incorporates safety features that minimize risks associated with fuel handling and flame operation, including appropriate volume ratios and wick positioning specifications. Regular audits of manufacturing facilities maintain adherence to quality management systems and continuous improvement protocols.

Environmental considerations include the selection of recyclable materials and manufacturing processes that minimize waste generation. The durable construction reduces replacement frequency, contributing to sustainable laboratory practices while maintaining cost-effectiveness over the product lifecycle.

Customization & Branding Options

Professional laboratory equipment suppliers can leverage comprehensive customization services that transform standard alcohol lamps into branded laboratory solutions. Custom packaging manufacturer capabilities enable the development of distinctive presentation formats that align with corporate branding strategies and market positioning requirements. These customization options include specialized labeling systems, color-coded cap variations, and custom documentation packages that enhance product differentiation in competitive markets.

Private labeling opportunities allow distributors and importers to establish their brand presence while maintaining access to proven manufacturing quality and technical specifications. The customization process accommodates various branding elements including logo integration, custom instruction materials, and specialized packaging designs that reflect brand identity and target market preferences.

Volume customization programs support large-scale procurement requirements for educational institutions and corporate laboratory networks. These programs can include specification modifications, custom cap color schemes, and specialized packaging configurations that facilitate inventory management and distribution logistics. The flexibility of the manufacturing platform enables adaptation to specific regional requirements and certification standards.

Technical customization options extend to wick specifications, fuel capacity variations, and specialized surface treatments that meet unique application requirements. These modifications maintain the fundamental design principles while accommodating specialized use cases and performance criteria that distinguish custom solutions from standard product offerings.

Packaging & Logistics Support

Professional packaging solutions ensure safe transportation and storage of alcohol lamps while maintaining product integrity throughout the distribution chain. The packaging design incorporates protective materials that prevent glass breakage and component separation during handling and shipping operations. Individual packaging units provide clear product identification and handling instructions that facilitate inventory management and end-user preparation procedures.

Bulk packaging configurations optimize shipping efficiency for large-volume orders while maintaining individual product protection standards. The modular packaging approach enables flexible order quantities and facilitates mixed-product shipments that accommodate diverse customer requirements. Packaging materials selection prioritizes environmental sustainability while ensuring adequate protection performance.

Documentation packages include comprehensive product information, safety guidelines, and maintenance instructions that support proper product utilization and compliance with laboratory safety protocols. Multi-language documentation options accommodate international distribution requirements and facilitate global market penetration strategies.

Logistics support services include coordination with international shipping providers, customs documentation assistance, and delivery tracking systems that ensure reliable product delivery to global destinations. The logistics network accommodates various shipping preferences including expedited delivery options for urgent requirements and consolidated shipments for cost optimization.

Why Choose Us

Our company brings decades of experience in laboratory equipment manufacturing and has established a strong presence across international markets through consistent quality delivery and technical innovation. This extensive background in precision glassware production enables us to understand the evolving needs of modern laboratories and educational institutions, ensuring that our Alcohol Lamp Conical Shape,with Ground-in Cap or Plastic Cap meets the highest standards of performance and reliability.

As a recognized metal packaging supplier and custom tin box supplier, our manufacturing capabilities extend beyond traditional glassware to encompass comprehensive laboratory solutions and specialized packaging requirements. This diverse expertise allows us to provide integrated solutions that address multiple aspects of laboratory equipment procurement and management. Our role as an OEM tin packaging solutions provider demonstrates our commitment to customization and quality manufacturing across various industry sectors.

Global collaboration networks enable us to serve customers across multiple continents while maintaining consistent quality standards and responsive customer support. Our multi-industry expertise encompasses educational, research, pharmaceutical, and industrial applications, providing deep understanding of diverse customer requirements and application challenges. This broad experience base ensures that our products meet the varied needs of international buyers, distributors, and importers.

Advanced manufacturing facilities incorporate state-of-the-art quality control systems and environmental management practices that align with international standards and sustainability objectives. Our commitment to continuous improvement drives ongoing product development initiatives and customer satisfaction programs that enhance the value proposition of our laboratory equipment offerings.

Conclusion

The Alcohol Lamp Conical Shape,with Ground-in Cap or Plastic Cap represents an essential component of modern laboratory equipment that successfully combines traditional functionality with contemporary manufacturing excellence. Its versatile design, dual cap system, and superior construction materials make it an ideal choice for educational institutions, research facilities, and quality control laboratories seeking reliable heating solutions. The comprehensive customization options, professional packaging support, and established global distribution network ensure that this alcohol lamp meets the diverse requirements of international markets while maintaining the highest standards of safety and performance. Through its proven track record of quality and reliability, this alcohol lamp continues to serve as a trusted tool for scientific advancement and educational excellence worldwide.