Introduction

Laboratory precision begins with the fundamental tools that enable accurate measurements and consistent results. The 1621 Volumetric Flask Graduated One Mark represents a cornerstone of analytical chemistry equipment, designed to meet the exacting standards required in research facilities, educational institutions, and industrial laboratories worldwide. This essential glassware combines traditional craftsmanship with modern manufacturing techniques to deliver exceptional accuracy and reliability in volumetric measurements.

As laboratory procedures become increasingly sophisticated and regulatory requirements more stringent, the importance of using high-quality volumetric glassware cannot be overstated. The 1621 Volumetric Flask Graduated One Mark addresses these critical needs by providing a dependable solution for preparing standard solutions, conducting analytical procedures, and maintaining the precision necessary for valid experimental results.

Product Overview

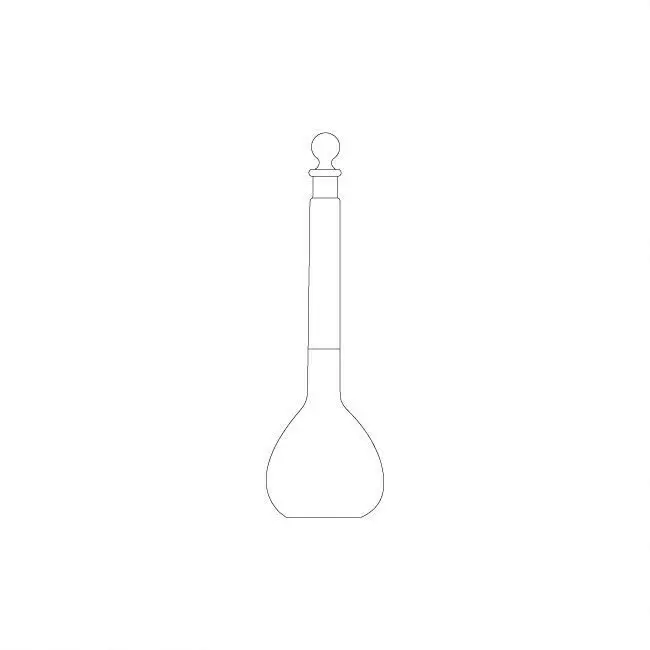

The 1621 Volumetric Flask Graduated One Mark embodies the perfect balance of functionality and precision engineering. Constructed from premium borosilicate glass, this volumetric flask features a distinctive pear-shaped body with a long, narrow neck that terminates in a precisely calibrated graduation mark. The design ensures optimal mixing characteristics while maintaining the accuracy required for quantitative analytical work.

This laboratory essential incorporates a ground glass joint system that provides secure connections with various laboratory accessories and ensures leak-proof operation during critical procedures. The flask's transparent construction allows for easy visual inspection of contents and facilitates accurate reading of the meniscus at the calibration mark. Each unit undergoes rigorous quality testing to verify conformance with international standards for volumetric accuracy.

The ergonomic design considerations extend beyond mere functionality, incorporating features that enhance user experience and laboratory efficiency. The wide base provides excellent stability during filling and mixing operations, while the narrow neck design minimizes evaporation losses and facilitates precise adjustment to the calibration mark.

Features & Benefits

Superior Glass Construction

The 1621 Volumetric Flask Graduated One Mark utilizes premium borosilicate glass that exhibits exceptional chemical resistance and thermal stability. This material choice ensures long-term durability while maintaining dimensional stability across a wide range of operating conditions. The glass composition minimizes interaction with chemical reagents, preserving the integrity of solutions and preventing contamination that could compromise analytical results.

Precision Calibration Technology

Each volumetric flask undergoes meticulous calibration procedures to ensure accuracy that meets or exceeds international laboratory standards. The single graduation mark is precisely etched using advanced techniques that provide clear, permanent markings resistant to chemical attack and repeated cleaning cycles. This attention to calibration detail ensures consistent performance across multiple uses and extends the operational lifespan of the equipment.

Enhanced Durability and Longevity

The robust construction methodology employed in manufacturing the 1621 Volumetric Flask Graduated One Mark incorporates stress-relief annealing processes that eliminate internal tensions in the glass structure. This treatment significantly reduces the risk of thermal shock damage and increases resistance to mechanical stress, making the flask suitable for demanding laboratory environments where equipment durability is paramount.

Applications & Use Cases

The versatility of the 1621 Volumetric Flask Graduated One Mark makes it indispensable across numerous laboratory applications. In analytical chemistry laboratories, these flasks serve as the foundation for preparing standard solutions with known concentrations, enabling accurate titrations and calibration procedures. The precision offered by this glassware is particularly valuable in pharmaceutical analysis, where regulatory compliance demands exceptional accuracy in solution preparation.

Educational institutions rely on these volumetric flasks to provide students with hands-on experience in quantitative analytical techniques. The clear graduation mark and stable design make it an ideal teaching tool for demonstrating proper volumetric measurement techniques and reinforcing the importance of precision in scientific work. Research laboratories utilize these flasks for preparing buffer solutions, conducting dilution series, and maintaining the standardized conditions necessary for reproducible experimental results.

Industrial quality control laboratories incorporate the 1621 Volumetric Flask Graduated One Mark into their routine testing protocols for product analysis and compliance verification. The flask's reliability and accuracy support critical quality assurance processes across industries including pharmaceuticals, food and beverage, environmental monitoring, and chemical manufacturing. Environmental testing laboratories depend on these precise instruments for preparing calibration standards and analyzing samples according to regulatory methodologies.

Quality Control & Compliance

Manufacturing excellence begins with comprehensive quality control systems that govern every aspect of production for the 1621 Volumetric Flask Graduated One Mark. Our quality assurance protocols encompass raw material inspection, in-process monitoring, and final product verification to ensure consistent performance characteristics. Each flask undergoes individual testing to verify volumetric accuracy, glass integrity, and marking permanence before approval for shipment.

International compliance standards guide our manufacturing processes, ensuring that every volumetric flask meets the stringent requirements established by recognized laboratory equipment standards organizations. Our quality management system incorporates continuous improvement methodologies that enhance product reliability while maintaining cost-effectiveness for our global customer base.

Traceability systems maintain detailed records of production batches, enabling rapid response to customer inquiries and supporting laboratory documentation requirements. Regular calibration of manufacturing equipment and ongoing validation of production processes ensure that quality standards remain consistent across all production runs of the 1621 Volumetric Flask Graduated One Mark.

Customization & Branding Options

Understanding the diverse needs of international laboratory markets, we offer comprehensive customization services for the 1621 Volumetric Flask Graduated One Mark. Custom marking options include institution logos, batch numbers, and specialized graduation schemes that meet specific application requirements. Our customization capabilities extend to packaging modifications, allowing distributors and large-volume users to incorporate their branding elements while maintaining product integrity.

Private labeling services support distributors in developing their branded product lines while benefiting from our manufacturing expertise and quality standards. Custom packaging solutions accommodate various distribution channels and regional preferences, from individual protective cases to bulk shipping configurations. Our design team collaborates with customers to develop marking schemes that enhance laboratory workflow efficiency while maintaining calibration accuracy.

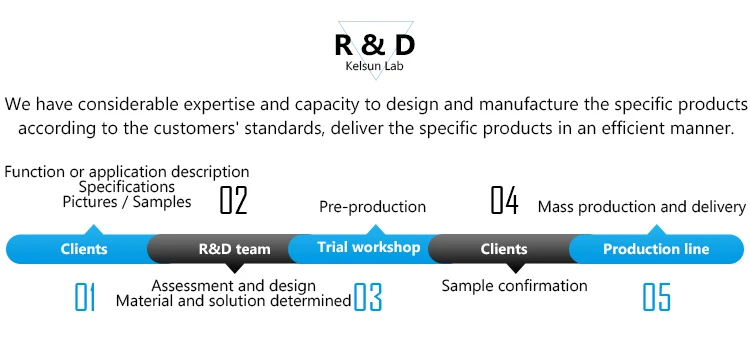

Specialized variants can be developed to meet unique application requirements or regional regulatory standards. Our engineering team works closely with customers to evaluate feasibility and develop cost-effective solutions that maintain the high-quality standards associated with the 1621 Volumetric Flask Graduated One Mark product line.

Packaging & Logistics Support

Protecting the integrity of precision glassware during transportation requires specialized packaging expertise that we have developed through years of international shipping experience. Each 1621 Volumetric Flask Graduated One Mark receives individual protective packaging using materials specifically selected for their cushioning properties and environmental resistance. Our packaging systems accommodate various shipping methods while ensuring product arrival in perfect condition.

Global logistics coordination ensures efficient delivery to international markets through optimized shipping routes and documentation procedures. Our logistics team maintains expertise in international trade requirements, customs procedures, and regional regulatory compliance to facilitate smooth transactions for distributors and end users worldwide. Inventory management systems support consistent product availability while minimizing storage costs for our distribution partners.

Sustainability considerations influence our packaging material selection and logistics planning, incorporating recyclable materials and optimized shipping configurations that reduce environmental impact. These efforts align with the growing emphasis on sustainable laboratory practices while maintaining the protection standards necessary for precision glassware.

Why Choose Us

Our commitment to excellence in laboratory glassware manufacturing spans decades of continuous innovation and quality improvement. As a recognized leader in precision laboratory equipment, we have established partnerships with distributors and end users across six continents, building a reputation for reliability and technical expertise that supports critical scientific work worldwide. This extensive international market presence demonstrates our ability to meet diverse regional requirements while maintaining consistent quality standards.

The 1621 Volumetric Flask Graduated One Mark represents just one example of our comprehensive approach to laboratory equipment manufacturing, where attention to detail and commitment to accuracy drive every production decision. Our multi-industry expertise enables us to understand the unique challenges faced by different laboratory environments and develop solutions that address specific application requirements.

Technical support services complement our manufacturing capabilities, providing customers with access to application expertise and troubleshooting assistance that enhances the value of their equipment investment. Our collaborative approach to customer relationships fosters long-term partnerships that contribute to scientific advancement and laboratory efficiency improvements.

Conclusion

The 1621 Volumetric Flask Graduated One Mark stands as a testament to the importance of precision instrumentation in modern laboratory operations. Through careful attention to materials selection, manufacturing excellence, and quality control procedures, this volumetric flask delivers the accuracy and reliability that scientific work demands. Its versatile design accommodates a wide range of applications while maintaining the durability necessary for long-term laboratory use. The combination of traditional craftsmanship and modern manufacturing techniques ensures that each flask meets the exacting standards required by today's analytical procedures, making it an essential tool for laboratories worldwide seeking to maintain the highest levels of measurement accuracy and experimental reproducibility.